November 19, 2025, is GIS Day, a day started in 1999 to highlight the diverse uses of geographical information systems (GIS). Earlier Locus blog posts on GIS Day covered augmented reality, dashboards, spatial queries, AI, and map mashups. This year, we look at another exciting technology: digital twins.

A digital twin is a virtual representation of real-world objects, created for monitoring, analysis, and prediction. NASA first created digital twins to assist with simulating performance of spacecraft (1). From there, digital twins expanded into manufacturing and construction, and then into utilities, healthcare, and renewable energy. Digital twins are also increasingly used in urban planning, especially as part of the “Smart Cities” movement (2).

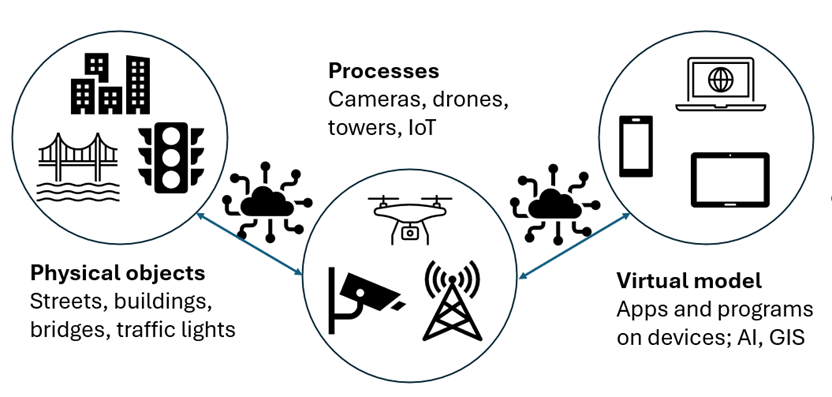

A digital twin has three parts: the physical objects being modeled; the virtual model of the objects; and the processes that keep the other parts coordinated. For example, imagine a digital twin of a city’s road network. The physical objects include the roads, bridges, and tunnels used by cars, trucks, buses, and other vehicles. The virtual model could be a mapping application storing the road network along with live overlays showing current traffic flow, accidents, road closures, and other events. The physical and virtual twins are kept coordinated through automated sensors and devices that report current road conditions.

The three parts of a digital twin for a city road network

Smart phone apps such as Google Maps or Waze have all the above components. If you ever use those apps to plan your driving route, you’re using a digital twin!

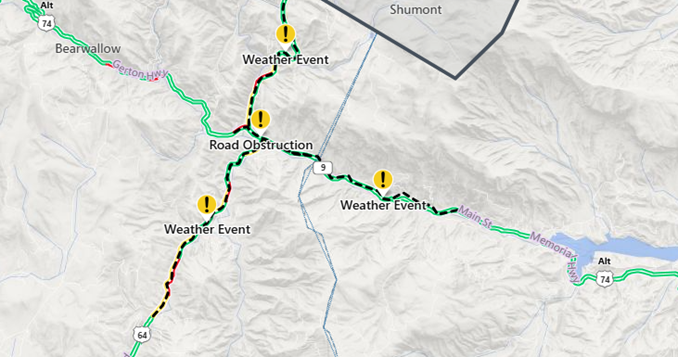

Digital twin of road network showing closure and weather events

Because real-world objects can be located on a map (an analog twin?) (3), GIS is a perfect tool for the virtual model piece of the digital twin. Such “geospatial digital twins” (4) permit more sophisticated modelling than phone apps support, especially when combined with 3D models and artificial intelligence (AI). They can also store changes over time to support predictions of trends based on past conditions. Urban planners can use geospatial digital twins of road networks to predict the effects of changes such as road closures, population growth, or expanded public transit, and thereby ensure the road network complies with all regulations.

Geospatial digital models can support applications in many areas beyond urban planning, including wildlife conservation, disaster response, infrastructure management, and cultural heritage preservation. At Locus, we are most interested in how digital twins help with compliance. A digital twin can support environmental compliance at a facility such as a manufacturing plant or refinery. Let’s assume we are looking at a refinery.

The three parts of the digital twin could be:

- Physical objects: the refinery assets such as pipelines, boilers, cracking units, and tanks.

- Virtual model: software applications in the Locus cloud, enhanced with GIS and AI.

- Coordination processes: delivery of data from the refinery to the Locus apps through sensors and IoT (internet of things) devices.

A geospatial digital twin in Locus software can help meet your compliance goals through:

- Monitoring of assets, processes, people, and facilities in real time.

- Tracking chemical emissions, spills, and releases.

- Allocating resources and staff in response to events.

- Alerting key personnel of accidents, incidents, or system defects that need immediate response.

- Maintaining operations by using AI to predict possible system or equipment failures.

- Simulating different scenarios (such as down time for maintenance or outages) and their effects.

- Providing training opportunities on safety procedures and operational processes.

- Cutting costs by improving processes and finding savings.

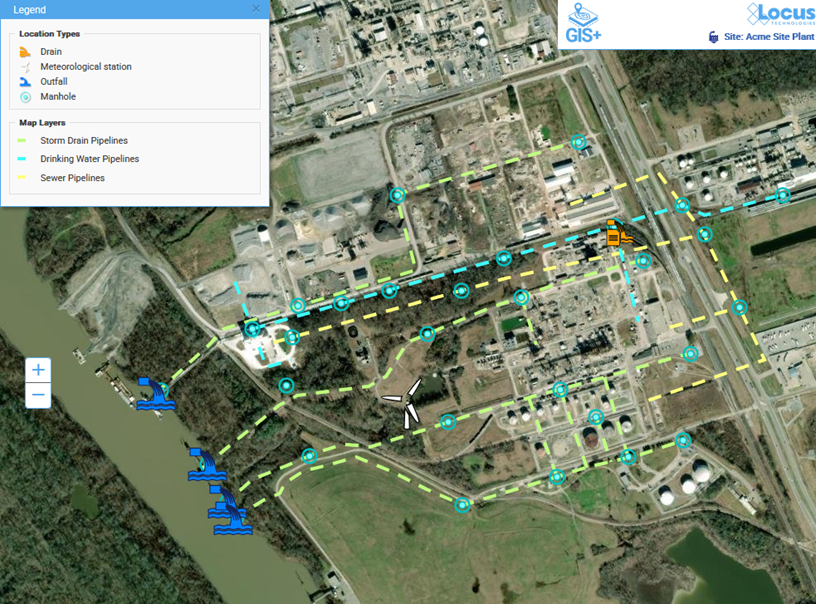

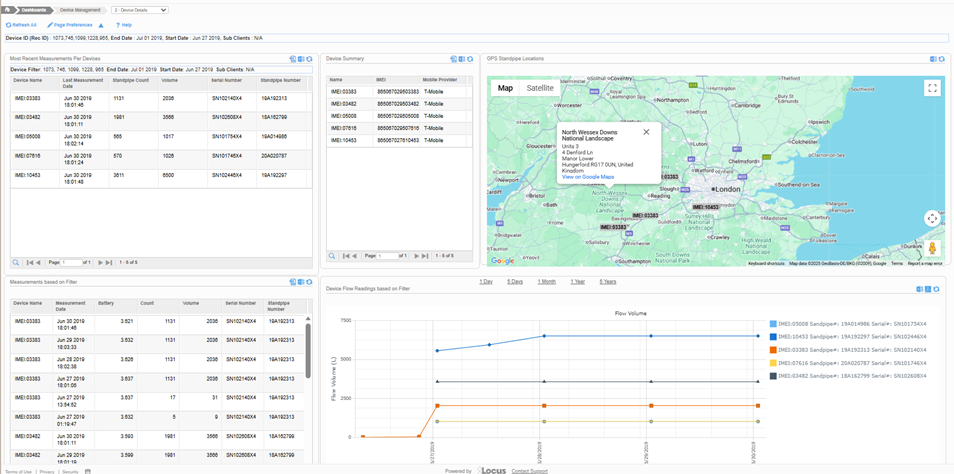

Below are two pictures of geospatial digital twins in Locus software.

A geospatial digital twin in Locus GIS+ showing tracked assets at a refinery

A geospatial digital twin in Locus Platform showing battery health and flow data from standpipes

Many of the benefits of a digital twin aren’t easily obtainable without one. For example, you can’t train operators how to respond to various emergency events by creating a real emergency and seeing what happens! A digital twin lets staff train with a simulated, safe environment. Similarly, facility monitoring can be done by having staff manually check for leaks, spills, or damage. With a digital twin, conditions are automatically collected through sensors and IoT. If the digital twin is enhanced with AI, models can proactively identify maintenance issues that may not be visible in a visual inspection, long before they are severe enough to cause problems. Furthermore, data that is automatically collected for a digital twin (as opposed to manually collected data on paper forms or logs) is more secure and available sooner. Operators can quickly analyze actual conditions against expected behavior and use this information to optimize plant operations.

Geospatial digital twins show much promise as a tool to help you meet your compliance goals. Contact Locus Technologies for more information!

Sources:

(1) Negri, Elisa; Fumagalli, Luca; Macchi, Marco (2017). “A Review of the Roles of Digital Twin in CPS-based Production Systems”. Procedia Manufacturing. 11: 939–948.

(2) https://en.wikipedia.org/wiki/Digital_twin#Urban_planning_and_the_construction_industry

(3) https://www.geoweeknews.com/blogs/geospatial-digital-twins-offer-unmatched-clarity-for-complex-systems

(4) https://www.esri.com/en-us/digital-twin/overview

Locus is the only self-funded water, air, soil, biological, energy, and waste EHS software company that is still owned and managed by its founder. The brightest minds in environmental science, embodied carbon, CO2 emissions, refrigerants, and PFAS hang their hats at Locus, and they’ve helped us to become a market leader in EHS software. Every client-facing employee at Locus has an advanced degree in science or professional EHS experience, and they incubate new ideas every day – such as how machine learning, AI, blockchain, and the Internet of Things will up the ante for EHS software, ESG, and sustainability.